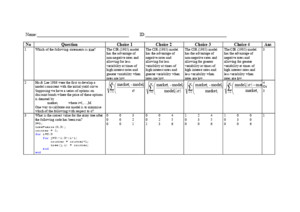

CSWIP 322 Questions

There is document - CSWIP 322 Questions available here for reading and downloading. Use the download button below or simple online reader.

The file extension - PDF and ranks to the Documents category.

Tags

Related

Comments

Log in to leave a message!

Description

Download CSWIP 322 Questions

Transcripts

CSWIP 32 THEORY PAPER Q A wwwetipsin Page 1 of 37 1 Signing off a product In an engineering fabrication industry the last activity in the sequence of manufacturing is load out or dispatch This activity cannot be initiated unless the product is signed off As a matter of fact signing the product off is assurance of quality which is authenticated by a technically competent person such as “ Senior Welding Inspector ” who makes sure that complete manufacturing of product has been carried out in accordance with applicable standard and sound engineering practices However before signing the documents the senior welding inspector should make enquiry which can give him the in sites of the past while product was being manufactured Typical questions can be as followed 1 What was the repair rate during production? 2 Whether any difficulties are encountered within the job? 3 Which is the critical area in this job or product? 4 Whether any concession or waiver were given, if yes why? 5 How were the weather conditions? 6 Whether there were any safety issues, fatalities, major accidents/incident etc…? 7 Whether there were any labour problems? 8 What was the general moral and standard of work amongst the inspection team(s)? Further to this he can start reviewing of documents and he should make sure that he attaches the following documents as a minimum 1 Quality control plan – ensure all stages are completed and signed off 2 Inspection check list – ensure all stages are completed and signed off 3 Verify material certificates such as mill test certificates; material traceability records lap reports etc… 4 Verify the following procedures which are to be attached and have all been approved a Welding b Repair c NDT d PWHT e Hardness f PMI g Hydrotest h Coating/Painting 5 Verify the qualification level and validity of the welder and NDT personnel 6 Verify the inspection reports of following disciplines and ensure that they cover all appropriate joints and structure a Visual b NDT c Dimensional control etc… 7 Verify calibration certificates of equipments and instruments such as pressure gauge, inspection tools and welding equipments etc… 8 Verify hardness test reports 9 Verify PMI reports 10 Verify PWHT reports and charts 11 Verify Hydro test reports and charts 12 Verify painting and coating inspection reports 13 Verify as built drawings are completed 14 Verify weld maps are available for traceability 15 Verify name plate, rubbing details are available when applicable 16 Verify c oncession request, NCR, site query etc… 17 Verify permit to work As a part of his own inspection he may be obliged to witness final hydrotest, visual inspection of completed parts As a matter of quality assurance he may view some radiographs at random and may even conduct radiograph audit CSWIP 32 THEORY PAPER Q A wwwetipsin Page 2 of 37 Finally, transit and tie down procedures should all have been approved by the relevant engineer prior to the final acceptance of the product and issue of any signed certificate of conformance 2 Duties of the Senior Welding Inspector Plan It is an agreed pre-determined structural path way that needs specific aim All projects inspection needs the following planning a Establishing inspection test plan and plan for all stages of inspection b Establish requires WPS and PQR c Plan for requires resources Ie manpower, inspection tools, etc, d Developing quality control procedures e Plan the work schedule ie type of inspection and at what times f Communication with superior and others Organize To make all necessary arrangement required to carry out or fulfil plan, this may involve the following a Any training and certification required b Staffing plan ie assigning work and area to inspectors c Procurement of inspection equipment and its calibration d Transportation to and fro from site e Accommodation and messing f Inspectors leave cycle Supervise Once the plan has been organized it is essential that controls are exercised so that the plan is successfully implemented a Supervise and evaluate inspectors work b Check inspection equipment condition c Organize the inspection activities to be completed in time d Take effective decision for solving quality related problems e Share your knowledge with technical discussion with all inspectors f Motivate the staff to meet standard of quality g Communicate with other department to improve procedure, investigate and advice on quality problems h Keep a record of day to day inspection activates and pending inspection to be completed i Supervise to maintain ISO related documents Auditing To carry out a periodic and systematic check on a system process to ensure that it has been carried out as specified Staff a All staff to be internal audited to ensure that they are maintaining all documents as per ITP b Whether all ISO related documents are maintained c Whether all welder details are up to date Equipment a Inspection tools to be checked for calibration and condition b Welding machine over calibration and condition Documentation a Check all inspection documents are maintained as per procedure b Check all NDT records CSWIP 32 THEORY PAPER Q A wwwetipsin Page 3 of 37 c Check welder qualification record d Randomly interpret Radiographic for all personals 3 Describe and sketch the following defects lamination, laps, bands and their differences Lamination Laminations are planes within the steel plate across (through thickness) which there is no metallic bond (separated in layers) They are typically a result of non-metallic inclusions and gas pockets formed in the ingot when it has been cast and as it solidifies In the steel mill the molten steel poured in moulds to form ingots While solidification is taking place huge amount of gases are released It is quite possible that some of these gases and non-metallic inclusions such as oxide coating of the bubbles, slag inclusions, refractory inclusions from erosion of the furnace may remain trapped in the solidified steel This ingot when rolled the gas pocket and inclusions inside get flattened in the forms of lamination This discontinuity adversely affects through thickness strength of steel and is not traceable by MPI or RT The only way to detect lamination is UT This discontinuity may also contribute to lamellar tear in thicker section Laps Laps are basically chunk of metal that has flown from the desired profile during operations such as rolling and hot forming This chunk of material is connected to the base metal at some locations and overhanging portion of the chunk simply lies on the metal without being the homogeneous part of it As it is surface def ect it can be found visually and can be confirmed by MPI Differences: lamination is a sub-surface defect lap is a surface defect Lap can be found in visual inspection and confirm by MPI Lamination can be confirmed by ultrasonic test only Bands As the ingot is forged and rolled the segregation are elongated and reduced in cross section If further processing is carried out, they may appear as very thin parallel lines of bands and is generally known as banding Banding is not usually significant 4 It has come to your attention that the morale of your inspection team appears to be low, a What could you have observed to determine this? b What would occur if this was not rectified quickly? c What could you do to lift low morale? Low morale can be identified by the following symptoms 1 lack of diligence 2 taking short cuts 3 ignoring safety procedures 4 not starting work promptly 5 taking long breaks 6 talking in groups and grumbling about minor matters 7 higher levels of absenteeism 8 Negligence (poor record keeping, not inspecting the weld etc) 9 complaints from TPI/Client Low morale may be result in the following 1 lack of control over production activities from quality point of view 2 poor productivity 3 substandard work output 4 delay in work schedule 5 lack of credibility to the organization Observing all above, it is imperative that lifting the low morale this can be done as follows

Recommended