Engineering Project Product Manager in Portland OR Resume Erik Pierson

There is document - Engineering Project Product Manager in Portland OR Resume Erik Pierson available here for reading and downloading. Use the download button below or simple online reader.

The file extension - PDF and ranks to the Presentations category.

Tags

Related

Comments

Log in to leave a message!

Description

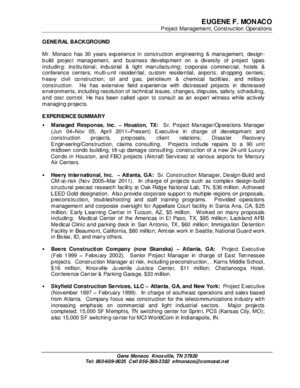

Erik Pierson is a Mechanical Engineer with wide-ranging experience, including global project management, design, development and process-challenged product / operations management

Transcripts

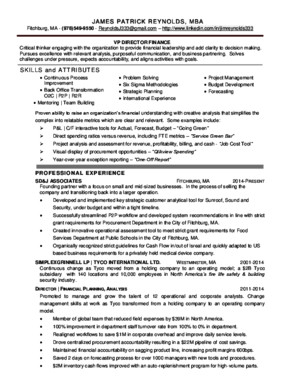

E RIK P IERSON Woodland, WA 98674 503-593-1047 erikpiersonfrontiercom D I R E C T OR / M ANAGER – E N G I N EE R I N G / P RODUCT D E V E LOPMEN T Product Lifecycle Management / Process Improvement / Cost Estimating / Six Sigma / RD / JIT Lean Manufacturing / Project Controls / CAD / DFM / B2B Support / QA / Strategic Planning Mechanical Engineer with wide-ranging experience, including global project management, design, development and process-challenged product / operations management Action-oriented goal seeker with strong practical and theoretical background Meeting or exceeding goals and targets with strong practical and theoretical background Defined ability to provide clear expression of vision, mission and strategy Driving innovation and diversification in large and small businesses Manages teams up to eight and budgets to 5M Can quickly contribute by: Leading complex projects from concept to launch on-time and under budget Building strong relationships and cooperation among stakeholders and customers Developing effective Statistical Tolerancing Design for Six Sigma Conveying complex specialized information to all levels of organization Excellent problem-solving skills with a proven ability to lead and motivate cross-functional teams Recognized hands-on approach to successfully promote new products and processes Grasping, designing and deploying highl technical and complex matters quickly internally and to external customers S ELECTED A CCOMPLISHMENTS Developed and launched patented product line ITT looked to establish connection technology as a mass market standard Negotiated joint development agreements Secured Long-term-agreement between ITT and Brasscraft Developed SureConnect and began production in 18 months Led design and build of fuel bundle program Cooper was awarded first fuel system program from Ford under commitment to FSE Led team to design, engineer, build and validate largest fuel bundle program in world for F- series trucks Embraced new global technologies to establish foothold in fuel and brake market segment Recognized as first supplier to embrace Full Service Engineering initiative Expanded product line capacity 11X ITT diversification process demanded increased product sales Presented data on cost reductions available through higher volume production Additional production allowed for greater automation investment and lower costs Boosted unit sales from 250K to 22M in twelve months Slashed tube forming cycle times 12%, establishing industry benchmark Cooper Standard Automotive looked to penetrate new US markets by adapting proven technology from Europe Completed thorough process failure mode and effects analysis (FMEA) to identify ideal process for F-Series truck Refined process and implemented on-time and under budget production in three facilities Reduced installation time on home plumbing product by 62% Diversification of ITT out-of automotive market necessitated quick connector for Home Plumbing Market Co-invented HydroLock product line, significantly reducing installation time Firm received Product Innovation Award and Strategic Product Development Partner Award based on success of product and market acceptance Applied Six Sigma process evaluation cutting production costs 11M Quality problem was costing Cooper Standard Automotive more than 250K annually Discovered fundamental design flaw exacerbated by inadequate production process Created new plan, erasing performance variation Achieved immediate 320K initial savings Grew award-winning diversified product line ITT Industries sought to diversify away from automotive market Fluid Handling Systems Division targeted new avenues for its lines Grew new industry sales 25M in two years Awarded ITT Gold Ring of Quality for achievement Increased production rates and improved retail margins Antiquated Cadet Manufacturing process was in need of repair Researched issues and crafted DOE to verify multiple flaws Created a new design, manufacturing process and assembly work cell, eliminating functional performance glitches Production rates grew 25% and retail margins improved 11% with associated production cost reductions Eliminated project losses with new process tracking coordination Thompson Metal Fabrication project required extensive scheduling for weekly reporting and project tracking Established master plan to stage supplier activity with internal fabrication and job site deliveries, displacing 2-5m in over-budget costs E RIK P IERSON P AGE 2 C AREER H ISTORY Director of Engineering , QwikLine Industrial Products, Inc, Offered entry into new startup in 2014 to design, engineer and develop, cradle-to-shelf, proprietary line of tools, crossing all market boundaries Established a secure Supply Chain and instituted significant cost saving opportunities in support of multiple production scenarios Defined product manufacturing costs, process flow, control plans and quality standards Project Manager , Thompson Metal Fabrication, 2012-2014 Recruited to support and manage large, fast-paced steel fabrication projects, using state-of-the-art MS Project Scheduling applications Performed in numerous positions, including on-site subcontractor management and contract negotiator, material takeoffs, component tracking and fabrication plans developer Engineering Manager , Cadet Manufacturing Co, 2006-2012 Responsible for cradle-to-customer launch of residential heating equipment Developed Solidworks PDM system and established FEA and CFD as tools, dramatically shortening product development life cycle Created a new design, manufacturing process and assembly work cell, eliminating functional performance glitches Grew production rates and improved retail margins with associated production cost reductions Industrial Business Unit Manager , ITT Fluid Handling Systems, 2000-2006 Named to build and manage autonomous industrial business unit capable of meeting five-year growth goal of 40M in new/product/new market sales Established customer, market and product strategies Leading engineering staff of eight, successfully diversified from parent firm ’ s core business in the automotive industry Earlier: Progressive positions of increased responsibility at Cooper Standard Automotive, culminating as Fuel and Brake Product Development Manager Managed all product design, development and validation for the first Full Service Fuel program awarded to the company by Ford Motor Co, Inc E DUCATION / T RAINING P ROGRAMS / C ERTIFICATIONS Received a BSMET degree from Wayne State University Graduated cum laude Member of Tau Alpha Pi, National Honor Society Completed Six Sigma Black Belt training through Six Sigma Methodologies CSWA Solidworks Mechanical Design Associate – 2015 ASE Master Mechanic Certification ASE Cylinder Head Specialist Certification ASE Block Machining and Repair Specialist Certification P ERSONAL Enjoy: Automotive Racing, NHRA, SCCA, In addition to: Boating, Skiing, Hockey, Horses and Fishing Active in the community, serving on the Woodland YMCA Community Swimming Pool Committee

Recommended